Installation Manual for OSDA Solar PV Modules

Regular Modules

![]() Safety Notes

Safety Notes

This manual elaborates on installation and safety use information for PV power generating modules (hereinafter referred to as module) of Ningbo Osda Solar Co.,Ltd. (hereinafter referred to as OSDA). Please abide by all safety precautions in this guide and local regulations.

Installation of modules requires professional skills and knowledge and is to be carried out by qualified personnel. Please read this manual carefully before installing and using this module. Installation personnel shall get familiar with mechanical and electrical requirements of this system. Please keep this manual properly as reference for future maintenance or upkeep or for sales and treatment of modules.

If you have any doubts, please contact OSDA global quality and customer service department for further interpretation.

Contents

3.2 Regular safety 4

3.3 Electric performance safety 5

3.5 Fire safety 6

4.1 Installation site and working environments 6

4.2 Selection of tilt angles 7

6.2 Cables and connecting lines 13

6.3 Connector 13

6.4 Bypass diode 14

7.1 Grounding by grounding clamp 15

7.2 Grounding by unoccupied mounting holes 16

7.3 The third party grounding devices 17

8 Operation and maintenance 17

8.1 Cleaning 17

8.2 Module appearance inspection 18

8.3 Inspection of connectors and cables 18

9 The list of the modification 18

First thank you very much for choosing OSDA PV modules!

This installation manual covers key electric and mechanical installation information, so please understand such information before installing OSDA modules. In addition, this manual also covers some safety information that you shall get familiar with. All contents in this manual are intellectual properties of OSDA which originates from long term of technical exploration and experience accumulation of OSDA.

This installation manual does not entail any explicit or implicit quality warranty and does not stipulate on compensation schemes for losses, module damages or other costs caused by or related to module installation, operation, utilization and maintenance process. If patent rights or the third party rights are infringed by use of modules, OSDA will not take any responsibility. OSDA reserves the rights for modifying product manual or installation manual without notice in advance.

If customers fail to install modules as per requirements set forth in this manual, the quality warranty provided for customers during sales will become invalid. In addition, suggestions in this manual are to improve safety of module installation, which are tested and proved by practices. Please provide this manual to PV system users for reference to and advise them of safety, operation and maintenance requirements and suggestions.

Mechanical and electrical installation of PV modules shall follow proper regulations such as electric law, building law and electric connecting requirements. These regulations differ with different installation sites, such as building roofing installation, vehicle-mounted application. Requirements may also differ with installation system voltage, DC or AC. Seespecific clauses in local authorities.

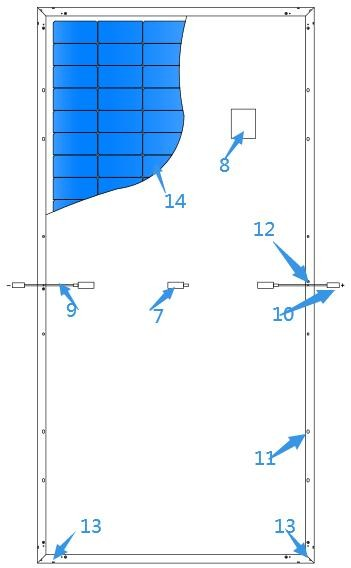

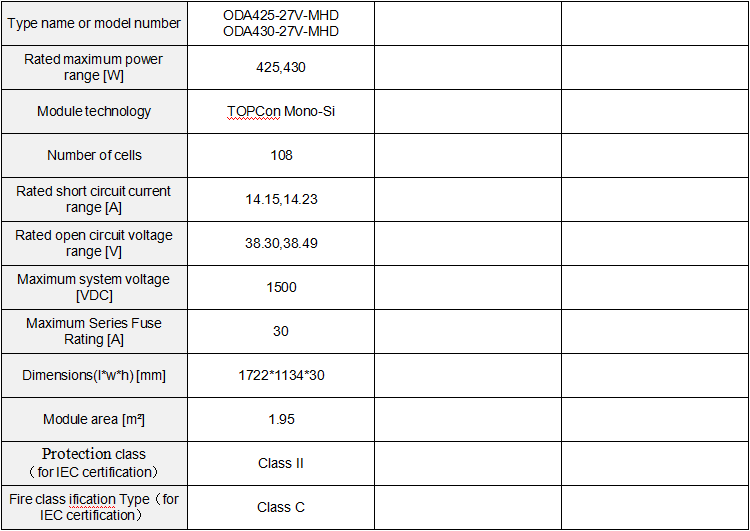

Each module is pasted with 3 labels providing information below:

1. Nameplate: It describes product type, standard rated power, rated current, rated voltage, open circuit voltage, short circuit current under testing conditions, certification indicator, maximum system voltage, etc.

2. Current level label: Divide modules as per their optimal working current and there are values: H, M or L (H means the highest current level). The best practice is to install modules with the same current level (such as H) in one strand in the process of installation.

3. Serial No.: Each module has a unique serial number which is solidified inside the module,permanently and it can be seen from front top of the module. Each serial number is put in before laminating of the module.

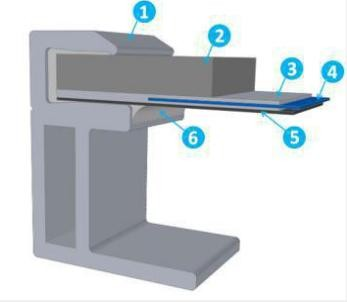

Figure 1 Module Section Structure and Components

OSDA module is considered to be in compliance with IEC61215 and IEC61730 only when the module is mounted in the manner specified by the mounting instructions below.

When the module is installed on roof, it is necessary to take the overall fire rating of the finished structure as well as later overall maintenance into account. The roofing PV system shall be installed after assessment by construction experts or engineers and with official analysis results for the entire structure. It shall be proved capable of supporting extra system bracket pressure, including PV module weight.

For your safety, please do not work on the roof without safety protective measures which include but not limited to fall protection, ladder or stair and personal protective articles.

For your safety, please do not install or handle modules in unfavorable conditions including butnot limited to strong wind or gust, damp or sandy roofs.

3.3 Electric performance safety

PV products will produce DC in the sunlight, so there may be electric shock or burning when touching module connecting line metals. 30V DC voltage or higher voltage can be fatal.

In case of no connected load or external circuits, modules can also produce voltage. Please use insulation tools and wear rubber gloves when operating modules in the sunlight.

PV modules doe not have switch. PV modules can only stop work when they are kept from sunlight or covered by cloth, hard board or light-proof materials or when front side of modules are placed on smooth and flat surfaces.

To avoid electric arc or electric shock hazards, please do not break down electric connection in loaded conditions. Wrong connections will also lead to electric arc or shock. Keep connectors dry and clean and make sure that they are in good working condition. Do not insert other metals into the connectors or carry out electric connection by whatever means.

Snow and water in surrounding environments will intensify light reflection and lead to increase of current and output power. And module voltage and power will increase under low temperature.

If module glass or packaging materials are damaged, please wear personal protective articles and isolate modules from the circuit.

Working is only allowed in dry conditions by means of dry tools. Do not operate when modules are wet unless you wear the proper electric shock protection device. Please operate following the cleaning requirements in this manual when cleaning modules.

Do not open OSDA Package in transportation and storage process unless the modules arrive at the installation site.

Do not damage the package and do not make packaged modules on pallet fall directly.

Do not exceed the highest layer limit indicated on the packaging carton when piling modules up.

Put packaging carton in the ventilated, rain-proof and dry places before unpacking of modules. Open OSDA’s packaging carton following unpacking instructions.

Do not hold the connecting box or wires to lift the entire module in any cases. Do not stand or walk on modules.Do not pile one module onto another.

To avoid glass damage, do not put heavy objects on module glass.

Be careful when placing modules on a surface and at corners in particular. Do not try to unpack the module or remove nameplate or parts of modules. Do not paint surface of modules or apply any other glues.

Do not damage, grad or scratch back film of modules.

Do not drill frame of modules, which may reduce frame loading capacity or lead to frame corrosion.

Do not scratch anodic coating of aluminum alloy frame except for grounding connection. Scratch may lead to frame corrosion and reduce frame loading capacity.

Do not repair glass or modules whose back film is damaged on your own.

Please consult local laws and regulations before installing modules and abide by requirements on building fire protection. Fire rating of OSDA modules is TypeC according to IEC61730.

The roof shall be coated with a layer of fireproof materials of such rating for roofing installation and make sure that the back plate and the mounting surface are fully ventilated.

Difference of roofing structures and installation modes will affect fireproof performance of buildings. Improper installation may lead to fire disasters.

To guarantee roof fire rating, the module frame shall be at least 10cm from the roof surface.

Adopt proper module accessories such as fuse, circuit breaker and grounding connector

according to local regulations.

The fire rating of this module is valid only when mounted in the manner specified in the mechanical mounting instructions.

Please do not use modules if there are exposed inflammable gases nearby.

4.1 Installation site and working environments

The modules can only be used on earth but not in outer space.

Do not focalize sunlight with mirrors or magnifying glass artificially onto modules.

OSDA modules shall be installed on proper buildings or other appropriate places (such as ground, garage, building outer wall, roof, PV tracking system) but shall not be installed on any mobile vehicles.

Do not install modules at such places as that are possible to be submersed.

OSDA suggests that modules be installed in the working environment with the temperature of -20 to 46 which is the monthly average highest and lowest temperature of the installation places.The extreme working environment temperature for modules is -40 to 85.

Make sure that installed modules do not suffer wind or snow pressure that exceeds the permissible maximum load.

Modules shall be installed in places free from shades throughout the year. Make sure there are no light-blocking obstacles in the installation places.

Carry out lightning protection for modules installed in places with frequent lightning and thunder.

Do not install modules in places with possible inflammable gases.

Modules can not be used in environments with too much hails, snows, flue gas, air pollution and soot or in places with strong corrosive substances such as salt, salt mist, saline, active chemical steam, acid rain, or other substances corroding modules, affecting module safety or performance.

Please take protective measures to ensure reliable and safe installation of modules in severe environments such as heavy snow, cold and strong wind or islands close to water and salt mist or deserts.

Tilt angle of modules: Included angle between module surface and horizontal surface; the module will obtain the maximum power output in direct facing of sunlight.

Modules are preferred to be south-facing in the north hemisphere and north-facing in the south hemisphere.

A specific installation angle shall be determined according to installation guide for standard modules or suggestions from PV module installer.

OSDA suggests that module installation tilt angle be no less than 10° so module surface dust can be washed away easily by rainfall and times of cleaning can be reduced. And it is easy for ponding to flow away and avoid water print on the glass due to long time of water ponding which may further affect module appearance and performance.

Make sure that module installation mode and bracket system are solid enough to bear the expected load, which is requisite assurance that the bracket installer must provide. Installation bracket system shall be tested and inspected by the third party testing institution with static mechanical analysis capacity in accordance with local national or international standards.

Module bracket shall be made from durable, corrosion resistant, ultraviolet proof materials. Modules shall be fixed on the bracket solidly.

Use higher brackets in places with heavy snow accumulation so the lowest point of modules will not be covered by snow for a long time. In addition, make the lowest point high enough so as to avoid sheltering of vegetations and woods or damage of flying sands and stones.

If modules are installed on brackets parallel to the roof or wall, the minimum gap between the module frame and the roof/wall shall be 10cm for air ventilation so as to prevent module line damage.

Do not make holes on glass or frame of modules.

Make sure the building is suitable for installation before installing modules on roof.

Moreover, seal permeable parts properly to prevent leakage.

The module frame has thermal expansion and cold contraction so the frame interval between two adjoining modules shall be less than 10mm.

Make sure that back plate of modules will not contact bracket into the module or building structures, especially when the module surface is imposed by pressure.

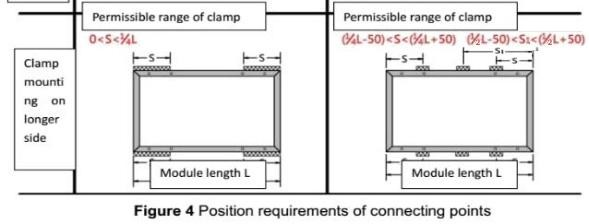

OSDA Solar Modules have been certified for a maximum design static load on the back of the Modules of up to 1600Pa*1.5 (i.e. wind load) and a maximum design static load on the front of the Modules of up to 3600Pa*1.5 (i.e. wind and snow load), depending on the clamp mounting (please refer to follow installing data for this information). And this is printed on the label of modules.

Module installation methods can not lead to electrochemical corrosion between module aluminum frame and different metals. Electrochemical potential difference of contacting metals shall not exceed 0.6V as is recommended in IEC61730 Appendix Flat Plate Photovoltaic Modules and Panels.

Modules can be installed horizontally or vertically.

5.2 Way of installation

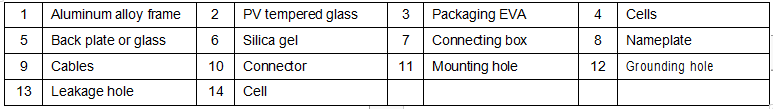

Module and bracket system connection can be realized by clamp or embedded systems. Installation shall follow the demonstration and suggestions below. If installation mode is different, please consult OSDA and obtain approval. Otherwise, modules may be damaged and quality warranty will become invalid.

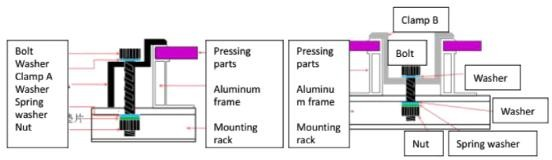

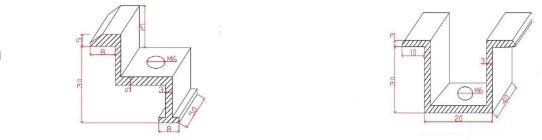

Use the special clamp to install modules. See Figure 3.

A. Fix modules on the bracket by metal clamp. The following clamps or those clamps recognized by module system installer are recommended.

Width: no less than 40mm; Thickness: no less than 3mm; Material: aluminum alloy; Bolt: M6.

B. Torque range for bolt fastening: 18N•m to 24N•m

C. The clamp shall not contact glass or make module frame deformed in any case. The contacting surface of the clamp and frame front side shall be neat and smooth. Otherwise, frame and module may be damaged. Make sure that the clamp will not produce shading effect. Drain holes can not be sheltered by the clamp.

Low/normal load working condition applies to most environments: the maximum static load

for backside is 1600Pa*1.5 (equal to wind pressure) and the maximum static pressure for the front side is 1600Pa*1.5 (for 4 clamps installation) (equal to wind pressure and snow pressure).

Higher load applies to severe environments (such as wind storm, heavy snow): the

maximum static load for backside is 1600*1.5Pa (equal to wind pressure) and the maximum static pressure for the front side is 3600Pa*1.5 (for 6 clamps installation) (equal to wind pressure and snow pressure).

6.1 Electric performance

Module electric performance parameters such as Isc, Voc and Pmax nominal values have ±3% error with those under standard testing conditions of: irradiance of 1000 W/m2, cell temperature of 25℃ and air mass of AM1.5.

Under normal conditions, a photovoltaic module is likely to experience conditions that produce more current and/or voltage than reported at standard test conditions. The requirements of the National Electrical Code (NEC) in Article 690 shall be followed to address these increased outputs. In installations not under the requirements of the NEC, the values of Isc and Voc marked on this module should be multiplied by a factor of 1.25 when determining component voltage ratings, conductor ampacities, overcurrent device ratings, and size of controls connected to the PV output.

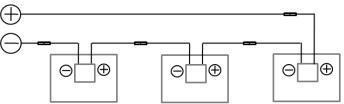

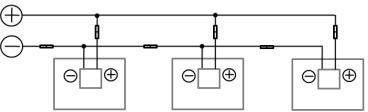

When modules are in series connection, the final voltage is sum of that of the single module. When modules are in parallel connection, the final current is sum of the single module. See Figur Modules with different electric performance models can not be connected in one series. Serial connection

Parallel connection

Parallel connection after series connection

Figure 5: Series connection and parallel connection circuit diagram

The number of modules in series connection in each strand shall be calculated as per requirements. The open circuit voltage value under the expected lowest temperature shall not exceed the maximum system voltage value stipulated for modules (OSDA module maximum system voltage is DC1500V according to IEC61730) and other values required by DC electric parts.

If modules are connected in series, the total voltage is equal to the sum of individual voltages. The recommended system voltage is as below,

System voltage ≥ N*Voc[1+TCVoc* (Tmin-25)]

If the modules are connected in parallel, the recommended number of modules in parallel is: maximum series fuse rating/Isc+1

Where

In module design, adopt enclosed connecting boxes with the protective level of IP68 for on-site connection to provide environmental influence protection for wires and connections and contacting protection for non-insulating electric parts. The connecting box has well connected cables and connectors with the protective level of IP68. These designs facilitate parallel connection of modules. Each module has two independent wires connecting the connecting box, one is negative pole and the other is positive pole. Two modules can be in parallel connection by inserting the positive pole at one end of wire of one module into the negative pole of the adjoining module.

Cables connecting modules shall satisfy the module maximum short circuit current. Adopt the special PV system sunlight resistant cables.

The minimum standards of cables connecting modules are:

When cables are fixed on the bracket, avoid mechanical damage to cables or modules. Do not press cables by force. Adopt special designed light resistant wires and clamps to fix

cables on the bracket. Though cables are light resistant and water proof, it is still necessary to prevent cables from direct sun radiation and water immersion.

Please keep connectors clean and dry. Make sure connector nuts are fastened before connection. Do not connect connectors that are damp or dirty or under other status. Protect connectors from direct sun radiation and water immersion or fall onto ground or roof.

Wrong connection may lead to electric arc and electric shock. Please make sure that all electric connection is reliable. Make sure all connectors with lock are fully locked.

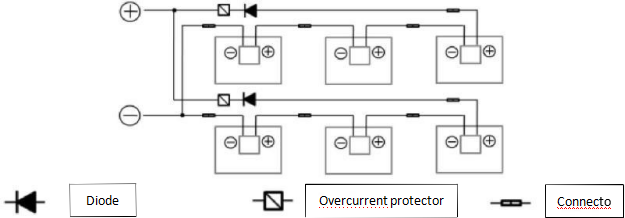

OSDA solar module connecting box contains bypass diode which is in parallel connection with the cell strands. If heat spot occurs locally with the module, the diode will come into operation to stop the main current from flowing through the heat spot cells with the view to restrain module heating and performance loss. But bypass diode is not the overcurrent protection device.

If the diode is found or doubted to get out of order, the installer or system maintenance supplier shall contact OSDA. Please do not try to open the module connecting box on your own.

N module numbers in series

Voc Open circuit voltage (refer to product label or data sheet)

TCVoc Temperature coefficient of open circuit voltage (refer to product label or data sheet) Tmin Minimum ambient temperature

Maximum series overcurrent protective device, where required.

If there is reverse current exceeding the maximum fuse current flowing through the module, use overcurrent protection device with the same specifications to protect the module; if parallel connection strands are more than 2, there shall be an overcurrent protection device on each strand of module. See Figure 5.

In design of modules, the anodized corrosion resistant aluminum alloy frame is used for rigidity support. For safety utilization and to protect modules from lightning and static-electricity damage, the module frame shall be grounded.

The grounding device shall be in full contact with inner side of the aluminum alloy and penetrate the frame surface oxide film.

Do not drill additional grounding holes on module frame.

To get the optimal power output, OSDA suggests that DC negative pole of the module array shall be grounded in installation of modules. Otherwise, the system power output will be reduced.

Module installation methods can not lead to electrochemical corrosion between module aluminum frame and different metals. Electrochemical potential difference of contacting metals

shall not exceed 0.6V as is recommended in IEC61730 Appendix Flat Plate Photovoltaic Modules and Panels.

Holes on the frame shall be drilled in advance and grounding signs shall be indicated.

These holes are only used for grounding but not for installation of modules.

A module with exposed conductive parts is considered to be in compliance with IEC61730 only when it is electrically grounded in accordance with the instructions presented below and the requirements of the National Electrical Code.

Where common grounding hardware (nuts, bolts, star washers, spilt-ring lock washers, flat washers and the like) is used to attach a listed grounding/bonding device, the attachment must be made in conformance with the grounding device manufacturer’s instructions.

OSDA recommends must thoroughly detail the attachment means in the module installation instructions.

Common hardware items such as nuts, bolts, star washers, lock washers and the like have not been evaluated for electrical conductivity or for use as grounding devices and should be used only for maintaining mechanical connections and holding electrical grounding devices in the proper position for electrical conductivity. Such devices, where supplied with the module and evaluated through the requirements in IEC61730, may be used for grounding connections in accordance with the instructions provided with the module.

Grounding methods below are permissible:

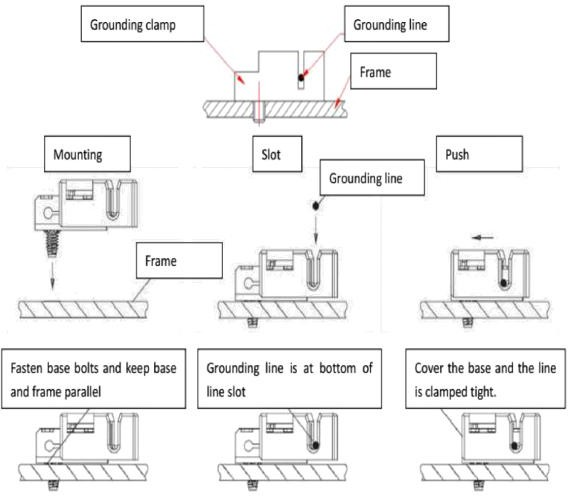

There is a grounding hole with the diameter of Ø4.2mm at the edge of the module back frame. The central line of the grounding sign and that of the hole overlaps and is consistent with the frame length direction.

Grounding between modules shall be confirmed by qualified electricians and grounding devices shall be manufactured by qualified electric manufacturer. The torque is recommended to be 2.3N•m.12 AWG copper core wire is used for the grounding clamp. And copper wires can not be pressed damaged in installatio

Figure 6 Grounding Clamp Installation

Note: TYCO. 1954381-1 (recommended) is used in figures above.

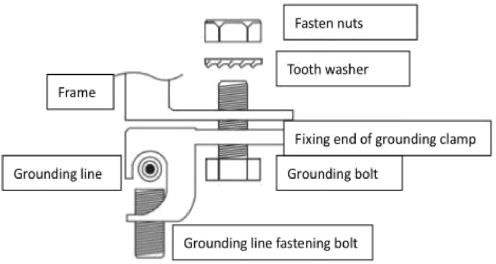

Mounting holes on modules that are not occupied can be used for installing grounding devices.

1. Align grounding clamp to the frame mounting hole. Use grounding bolt to go through the grounding clamp and frame.

2. Put the tooth side of the washer on the other side and fasten the nuts. The recommended torque for nut fastening is 2.0Nm to 2.2Nm.

3. Put grounding lines through the grounding clamp and grounding wire material and dimension shall meet requirements in local national and regional law and regulations.

4. Fasten bolts of grounding lines and installation ends.

Figure 7 Way of Installation

The third party grounding device can be used for grounding of OSDA modules but such grounding shall be proved to be reliable. Grounding device shall be operated in line with stipulations of the manufacturer.

Carry out regular inspection and maintenance for modules and this is the user’ responsibility within the quality warranty period in particular; and, inform the supplier within two weeks when modules are found to be damaged.

Accumulated dust on module surface glass will reduce the power output and lead to local heat spot, such as industrial waste water and birds droppings. The degree of influence is determined by transparency of wastes. Small amounts of dust will affect sunlight strength and evenness but are not dangerous and power will not be reduced remarkably in general.

During operation of modules, there shall be no environmental factors projecting shades or shelter partial or the entire module, including other modules, module system bracket, birds, dust, soil or plants. These will reduce output power. OSDA suggests that the module surface should not be sheltered in any case.

Frequency of cleaning depends on dirt accumulation speed. In normal situations, rainwater will clean the module surface and the cleaning frequency is reduced therefore. It is suggested to use damp clean water sponge or soft cloth to wipe the glass surface. Do not use acid and alkaline detergents to clean modules.

Check module appearance defects visually, especially:

1. Module glass cracks.

2. Corrosion at welding parts of the cell main grid: it is caused by moisture into the module due to damage of surface packaging materials during installation or transportation.

3. Check whether there is burning traces on the module back plate.

8.3 Inspection of connectors and cables

It is suggested to carry out a preventive inspection once every 6 month:

1. Check connector sealing and cable connection solidness.

2. Check whether sealant of the terminal box is cracking with gap.

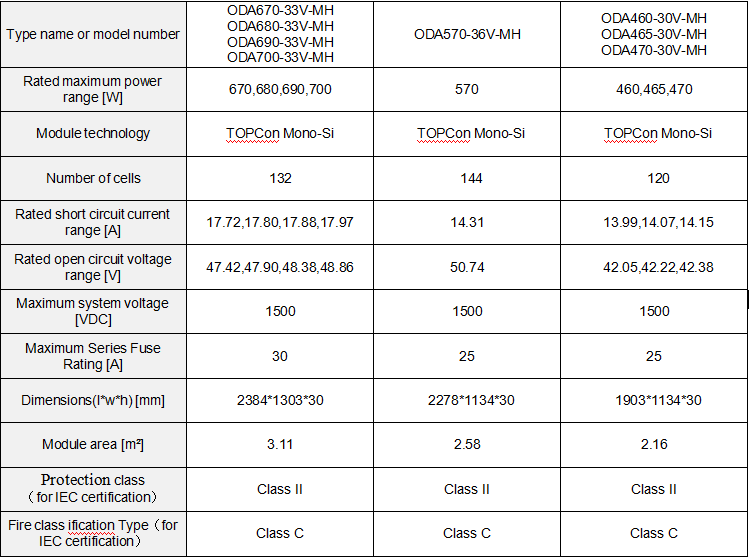

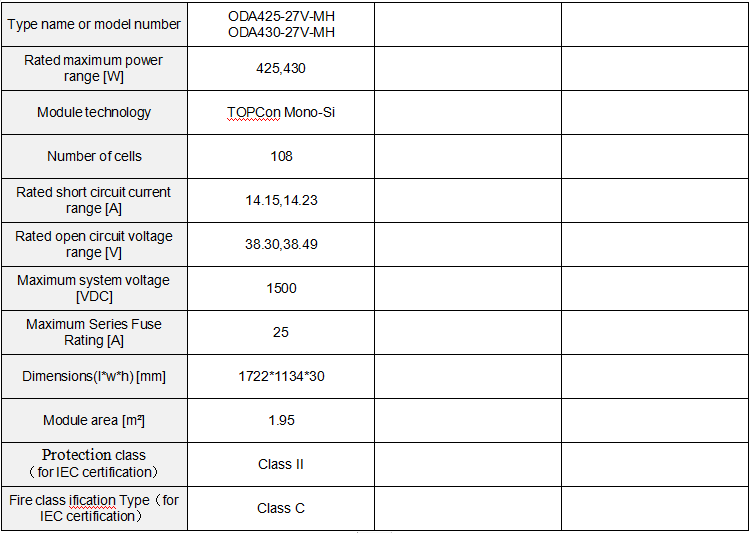

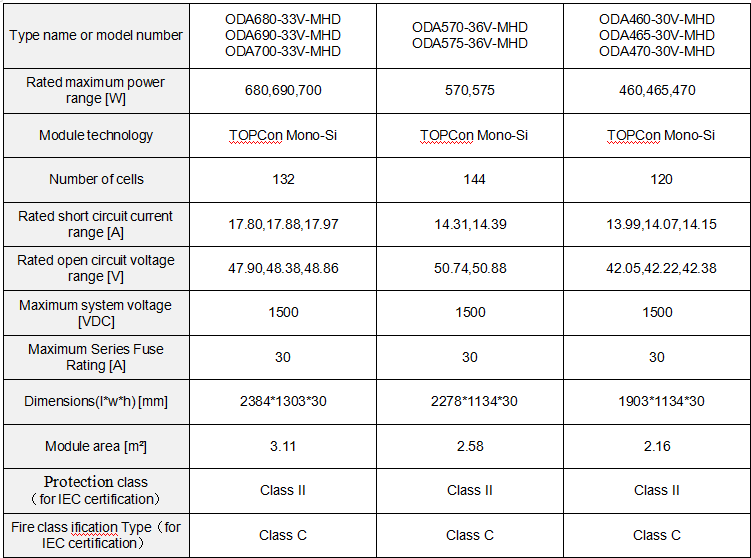

This installation manual is applicable to the following models

PV Modules with Half-cut 210mm TOPCon Mono-crystalline Silicon Solar Cells:

ODA700-33V-MH ODA690-33V-MH ODA680-33V-MH ODA670-33V-MH

PV Modules with Half-cut 182mm TOPCon Mono-crystalline Silicon Solar Cells:

ODA570-36V-MH ODA470-30V-MH ODA465-30V-MH ODA460-30V-MH ODA430-27V-MH ODA425-27V-MH

Double Glass PV Modules with Half-cut 210mm TOPCon Mono-crystalline Silicon Solar Cells:

ODA700-33V-MHD ODA690-33V-MHD ODA680-33V-MHD

Double Glass PV Modules with Half-cut 182mm TOPCon Mono-crystalline Silicon Solar Cells:

ODA575-36V-MHD ODA570-36V-MHD ODA470-30V-MHD ODA465-30V-MHD ODA460-30V-MHD ODA430-27V-MHD ODA425-27V-MHD

characteristics are within ±3 percent of the indicated values of Isc, Voc and Pmax under standard test conditions (irradiance of 1000 W/m2, AM 1.5 spectrum, and a cell temperature of 25°C ).